Boost Workshop Workflow: Top Charger Placement Strategies for Pros

In This Article

- Place chargers near high-use work zones for accessibility.

- Separate charged and depleted batteries with clear labelling.

- Wall-mount stations for improved cable management and safety.

- Ensure charger areas are ventilated and safely wired.

- Segment multi-charger hubs to prevent circuit overloads.

- Secure valuable batteries in lockable units with ventilation.

- Use smart chargers and maintain them regularly.

- Avoid common errors like overcrowding and improper charger use.

- Upgrade to intelligent chargers for smarter energy use.

Why Charger Placement Matters in Workshop Efficiency

Enhanced accessibility and reduced clutter

Proper workshop charger placement is more than just a matter of convenience—it is fundamental to productivity, safety, and tool longevity. When chargers are positioned with intent, they reduce tool retrieval time, prevent battery-related hazards, and promote better cable management. A disorganised charging area can create bottlenecks in workflow, particularly in fast-paced environments where multiple cordless tools are continuously in use.

By centralising and clearly defining charging hubs, technicians spend less time tracking down fully charged batteries or tangled leads. Moreover, having a clean, high-accessibility charging zone minimises disruptions in daily work routines. This approach not only saves time but also promotes accountability among staff through clearly assigned charging slots for shared tools. Workshop charger placement directly impacts uptime, which translates to increased output and satisfied clientele.

Choosing the Ideal Charger Location Near Your Work Zone

Prioritise visibility and proximity to tools

Strategic placement of chargers near primary workstations is crucial to efficient operations. Place chargers where they are highly visible and easy to access during both idle and peak operation periods. This is particularly important in environments where tight schedules demand on-the-fly battery swaps. Install chargers on surfaces close to frequently used stations, ideally at waist-height to prevent bending or heavy lifting.

It’s essential that workshop charger placement avoids high-traffic lanes or paths where cords may become tripping hazards. Instead, utilise underutilised wall space or mount vertically to save room. In shared spaces, consider deploying colour-coded or labelled zones per team or task to personalise charger access and limit confusion.

“Our downtime dropped by 25% once we reorganised charger stations within 2 metres of workbenches.” – Lead Technician at Shoreline Fabrications

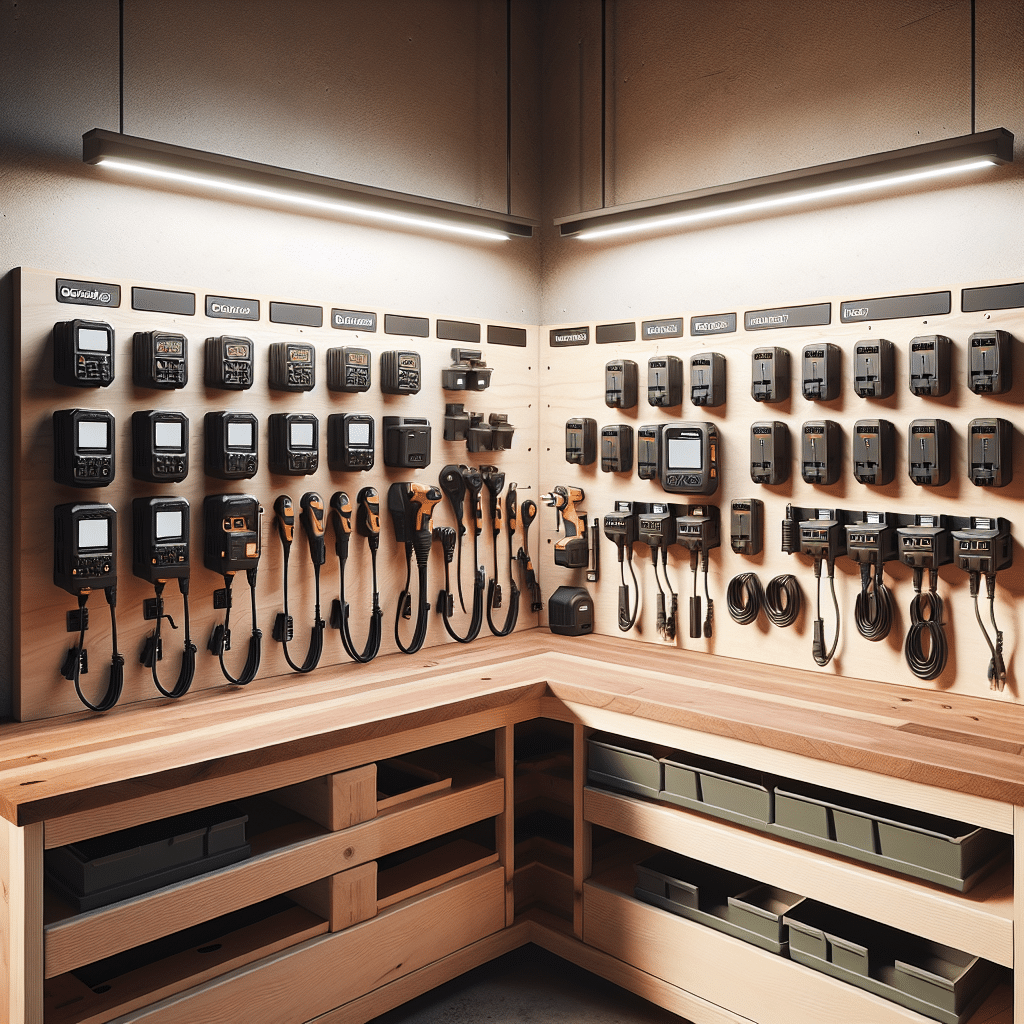

Wall Mounting for Clean Cable Management

Using hooks, clips, panels, and ducts

Wall-mounted charger stations offer enhanced visual organisation and significantly reduce tripping hazards caused by loose cables. Mounting your chargers at chest or eye-level on designated wall panels allows for better airflow and eliminates bench surface clutter. Use heavy-duty wall hooks and cable clips to route power cables neatly. For complex layouts, incorporate cable ducts and raceways to streamline wiring without compromising access.

Reinforced steel pegboards or modular panels offer an adaptable solution. Chargers can be shuffled or reattached as tasks and tools evolve. Ensure mounting brackets can take the load of both the charger and battery types in use. Avoid mounting chargers where dust build-up is frequent, such as near sawdust-creating tools. Instead, opt for cleaner sections of the workshop where ventilation is superior and interruptions are minimal.

Labeling Battery Stations for Better Battery Rotation

Keep charged and drained batteries clearly separated

Implementing a good labelling system in your workshop charger placement protocol ensures efficient battery rotation and maintains tool efficiency. Unlabelled chargers and batteries often lead to unnecessary recharging of already-charged cells, reducing overall lifespan due to overcharging cycles. Create a clear “charged” and “used” section on your battery shelf using waterproof stickers or magnetic tags.

Additional options include integrated LED indicators or simple whiteboards for manual entry. Staff members should be trained to place drained batteries in one section and retrieve only from the charged zone. This scheme avoids ambiguity and ensures that every battery gets used evenly, prolonging battery shelf life and reducing waste. For workshops operating across shifts, this systematic approach is vital for continuity and inter-team consistency. Learn more about Efficient Workshop and Tool Power Management

Integrating Ventilation and Safety in Charger Areas

Ensure airflow, fire prevention, and electrical grounding

Every charger station requires careful consideration of thermal and electrical safety. Lithium-ion batteries—commonly used in modern cordless tools—generate minimal, yet cumulative heat. Placing too many chargers in an enclosed or unventilated corner can pose serious overheating risks. Ensure that each workshop charger placement area is nestled in a ventilated space with at least 10 cm clearance around each unit.

Use fire-retardant surfaces or mats under primary chargers. Where possible, install surge protectors or circuit breakers dedicated to charger circuits. Using reliable, grounded power strips with proper load ratings will help distribute electricity safely. Some advanced charger stations come with temperature warnings or automatic shutoffs, and should be prioritised when purchasing new units. Smart workshop layout techniques for efficiency

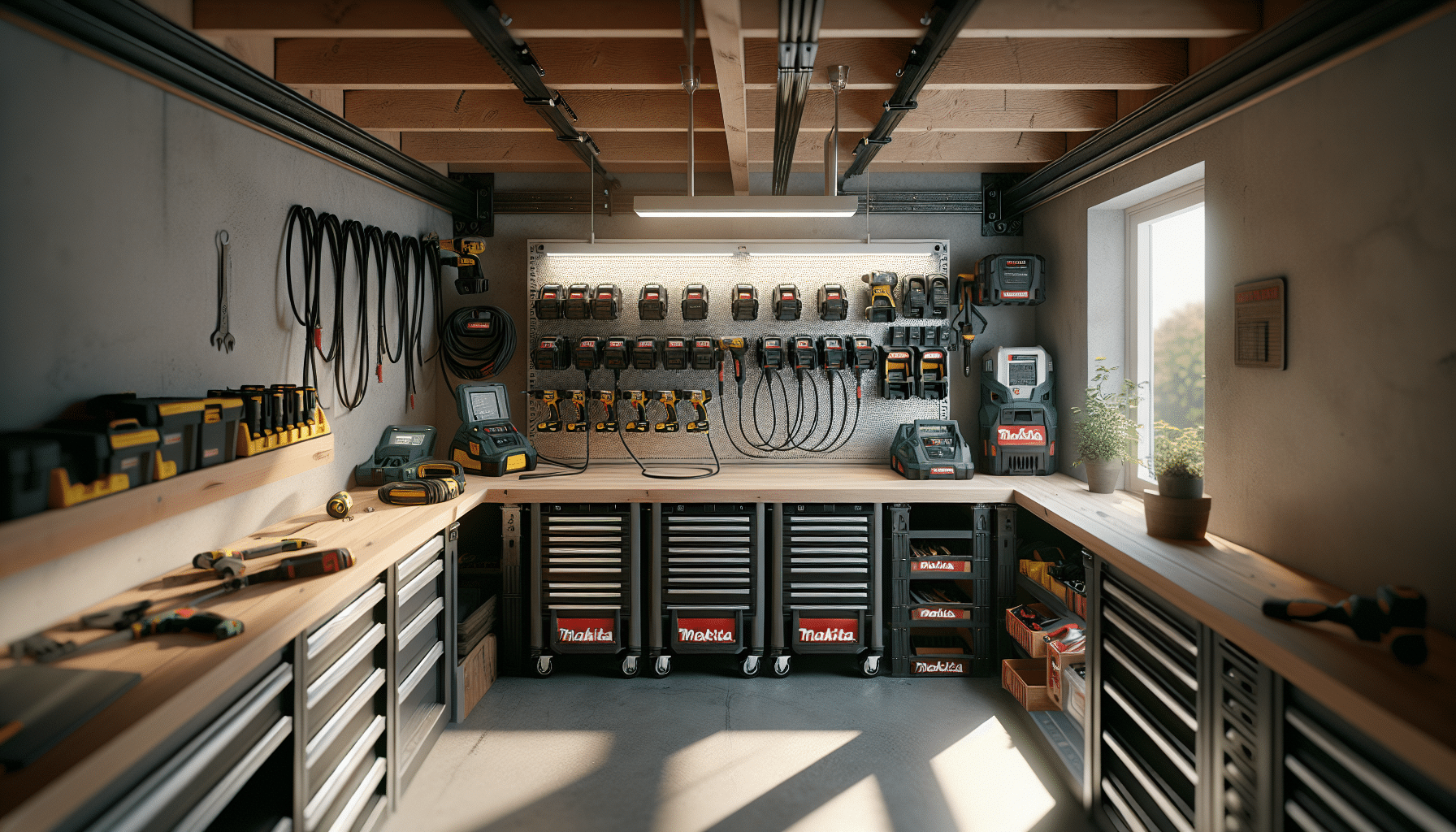

Setting Up Multi-Charger Power Distribution Hubs

Split loads strategically for optimal charging

As a workshop grows, so does its demand for simultaneous charging. To avoid overloading circuits or overwhelming single-wall outlets, configure multiple power distribution hubs. Segment your charger units by task or tool category. For instance, have a separate charging hub for joinery, metalwork, and general maintenance. Each hub should plug into a designated, load-tested socket, preferably on different breakers.

Use industrial-grade power rails with sufficient spacing between outlet ports to prevent heating. Always check the combined amperage draw of all chargers and ensure it’s well within the circuit’s threshold. Investing in load-monitoring smart hubs can alert users to imbalances or spikes in electricity usage. This level of detail is often overlooked but can be critical in long-term tool management. Read a related article

Storage Ideas: Drawers, Charging Shelves, and Lockable Units

Improve security and space conservation

Security and neatness go hand-in-hand when planning workshop charger placement systems. For workshops with high-value batteries or those used by multiple crews, locking drawer units are ideal. Choose units with integrated ventilation and cable cut-outs at the rear to allow chargers to remain plugged in even while stored.

Alternatively, open shelving specifically designed for battery charging offers the best blend of visibility and easy access. Adjustable shelving is preferred so bulkier tools can be charged alongside battery packs. Stackable plastic containers with dividers can serve as temporary stations for rotating batteries. Add foam linings to protect battery ports and terminals from dust penetration. Boost EU reach with multilingual website SEO

Daily Routines: Battery Swap Stations and Maintenance

Boost uptime with process consistency

Incorporating battery swap stations into your daily workflow sets a foundation for predictable uptime. Position a table or bench near entrances, where incoming or departing staff can deposit drained units and pick up fully charged ones. This queue-like system functions similarly to IT drop-off desks and promotes real-time availability without interfering with active work areas.

Daily maintenance checks should also be incorporated into your workshop charger placement routine. Encourage technicians to wipe charger terminals, inspect plug points, and log battery performance weekly. Regular maintenance reduces long-term faults and instils a culture of asset responsibility among personnel.

Common Charger Mistakes to Avoid

Overcrowding, overheating and underutilisation

Some common errors can compromise even the most thoughtful workshop charger placement strategy. Chief among these is overcrowding—placing too many chargers and batteries on one surface or power outlet. This is not only inefficient but could potentially lead to circuit trips or fire risk. Another typical mistake includes using one charger for all battery types indiscriminately, which shortens battery life through incorrect charge cycles.

Underutilisation of smart chargers is also prominent. Many modern chargers offer diagnostic feedback and power optimisation features. Ignoring these advantages results in underperformance of otherwise top-tier tools. Lastly, locating charger stations too far from primary work zones adds unnecessary steps and disrupts workflow fluidity. Mapping out workstation–charger proximity should always be foundational in the design plan.

Upgrade Picks: Best Chargers for Makita-Compatible Tools

Introducing the Torxup VoltGuard 6500

Among the best-in-class charger upgrades, the Torxup VoltGuard 6500 has risen as a standout option for Makita-compatible tools. It features dual slots, rapid charging cycles up to 6.0Ah within 30 minutes, and intelligent voltage monitoring. Its smart interface not only prevents overcharging but also offers visual battery diagnostics. Rugged, wall-mountable, and IP54 dust-resistant, it’s ideal for heavy-duty workshop environments.

Additional integrated cooling fans ensure charger longevity and battery health. When selecting charger upgrades, always check compliance with the manufacturer’s battery warranty conditions. It’s advisable to look for certifications like CE and BS1363 for UK-based operations. If your team uses multiple tool brands, consider hybrid docking stations with switchable ports to reduce charger sprawl and enhance your entire workshop charger placement plan.

Conclusion: Power Your Workshop Smarter

Workshop efficiency hinges on more than just tool effectiveness—it’s about planning, especially when it comes to power management. Through intentional workshop charger placement, you can reduce downtime, limit workplace hazards, and extend the lifespan of expensive batteries. From wall mounting to labelling, and from routine maintenance to technology upgrades, every component plays a role in streamlined operations.

As technology continues to evolve, so will charger capabilities and workshop layout trends. Stay proactive, regularly audit charging setups, and encourage daily accountability. These simple changes lead to substantial, quantifiable improvements in output, efficiency, and tool reliability.

Great guide on boost-workshop-workflow-charger-placement-strategies – Community Feedback

What is the best place to position a workshop charger?

The best position is wall-mounted near your main workbench with easy access, adequate ventilation, and minimal cable clutter for efficient use.

How can charger placement impact workshop workflow?

Well-placed chargers reduce downtime, prevent tool clutter, and ensure charged batteries are always ready, directly boosting productivity.

Which chargers are recommended for busy workshops?

Rapid chargers like the Torxup VoltGuard 6500 are ideal due to fast charging, durability, and integrated safety features suitable for active workshops.