How Fast Charging Significantly Cuts Overtime on Job Sites

In This Article

- Minimal battery downtime improves tool readiness and lowers unplanned overtime.

- Smart chargers with high amp ratings and safety features are vital investments.

- Fast charging systems offer measurable ROI within months of adoption.

- Battery longevity is unaffected when using properly matched intelligent chargers.

- Contractor feedback supports productivity and safety boosts with fast chargers.

- Top models include Milwaukee M18, DeWalt DCB104, and Makita DC18RD.

- Real-time tool readiness helps maintain scheduling and contractual milestones.

- Energy optimisation and tracking features aid long-term cost control.

Why Downtime Drives Up Job Site Overtime Costs

Understanding the Impact of Uncharged Tools

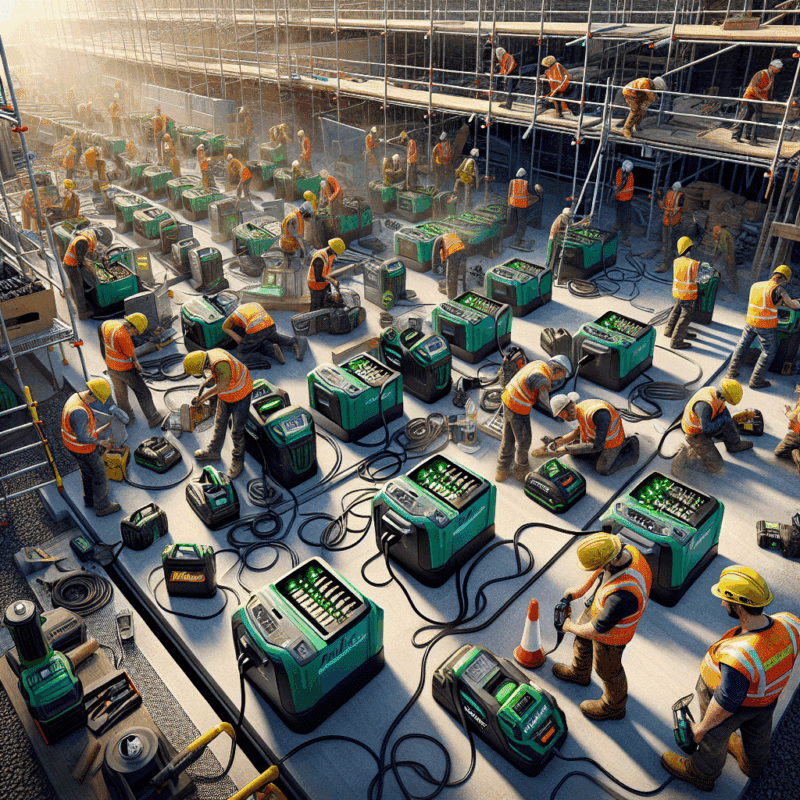

On any fast charging job site, the cost of downtime can be substantial. The moment a critical power tool runs out of charge, productivity grinds to a halt. When you multiply this across a team of workers and throughout the duration of a full workday, the cost in lost time and increased overtime quickly adds up. Many sites still rely on a shared pool of batteries and limited chargers, which often results in queues, scheduling conflicts, or non-functional tools during time-sensitive tasks.

Consider the repercussions on tasks requiring consistent tool availability, such as drilling, grinding or sawing during structural framing. If a team member pauses to wait for a battery to recharge, other members relying on that progress may also be delayed. Downstream dependencies create a compounding effect, often leading to overtime shifts to compensate for the lost productivity. This issue is exacerbated during peak project phases when deadlines are tight.

Worse still, rushed work during overtime can reduce quality and increase the likelihood of errors that must be corrected later. Inefficiencies spiral, and the root cause – inadequate charging infrastructure – remains unaddressed. The direct link between inconsistent tool charging and creeping overtime costs is now undeniable.

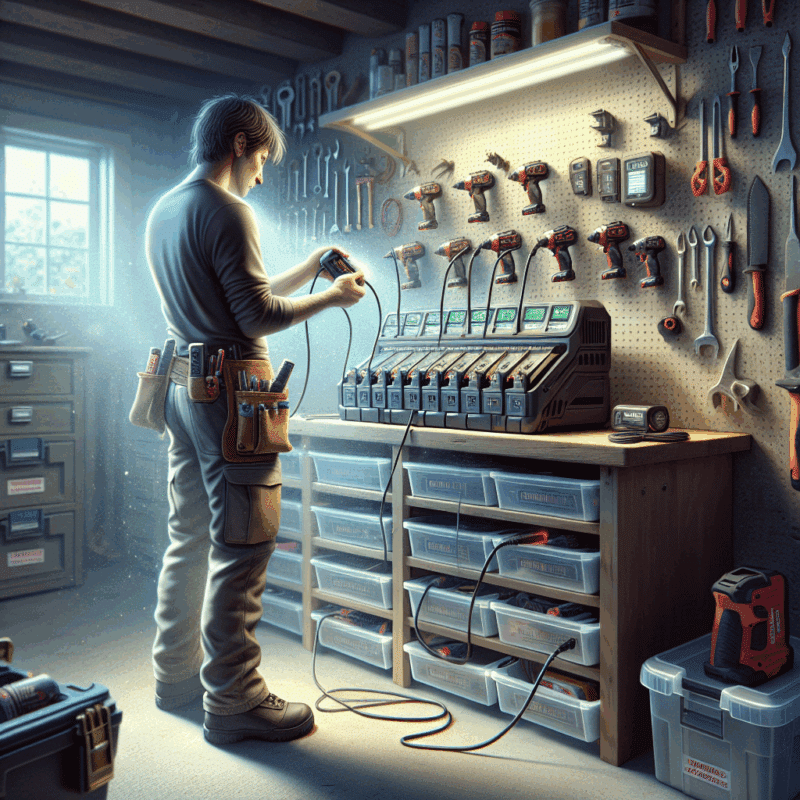

The Solution: Integrating Fast Charging Stations On-Site

Speeding Up Battery Turnaround Times

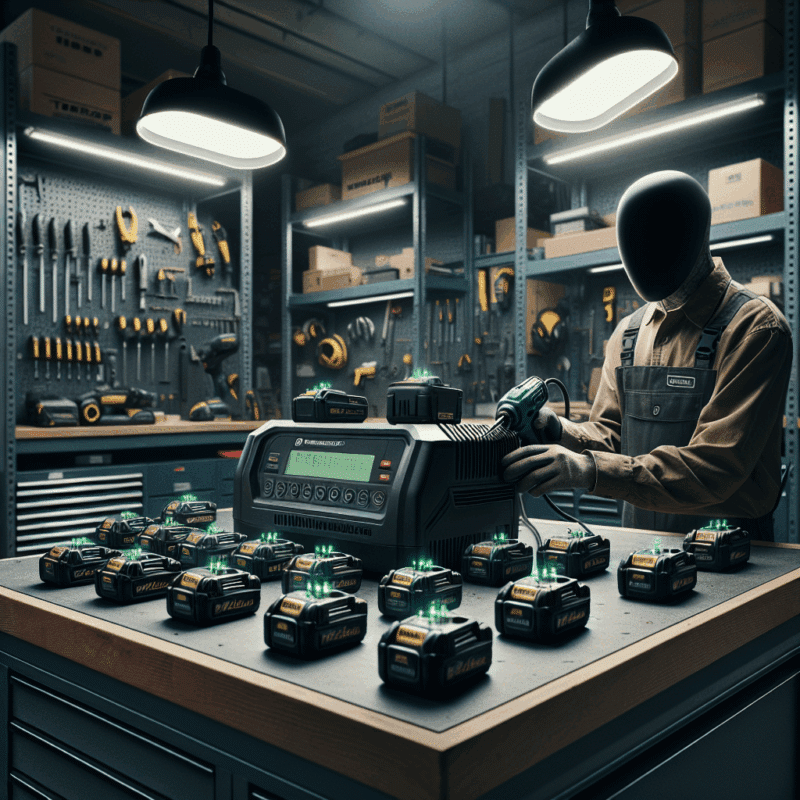

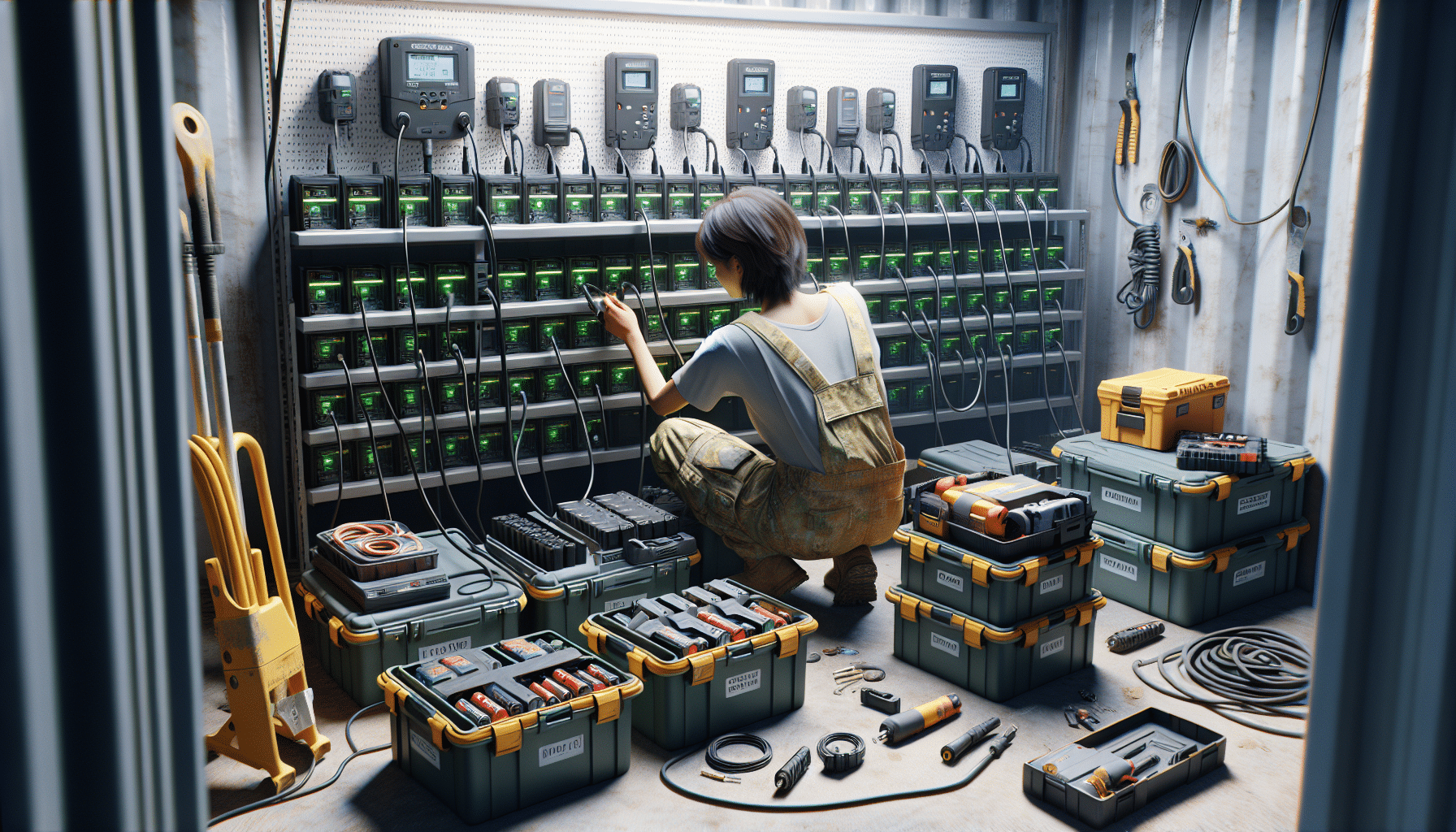

To effectively combat inefficiencies, adopting a fast charging job site model is essential. Installing multiple fast charging stations across the site ensures that batteries are always being prepped for the next rotation. This eliminates queues and empowers team leads to coordinate tasks with confidence, knowing that power tools will remain operational.

Key advantages of fast charging integration include dramatically reduced charging times—up to 75% faster compared to standard chargers—and the ability to top up batteries during short breaks or equipment changes. Many contractors are reporting battery turnover improvements that add up to multiple hours of productivity per day.

The placement of charging units also matters. Distributed chargers, positioned strategically throughout the site, allow for efficient charge-swapping without disrupting workflow. Some of the most successful implementations even include solar-powered units on larger contracts or container-based mobile charging rooms that can be redeployed as the project advances.

A fast charging job site saved us two hours a day across the crew – that’s nearly 40 hours of overtime costs we no longer incur weekly.

The Tech Behind Rapid Chargers

Why Amp Ratings and Safety Features Matter

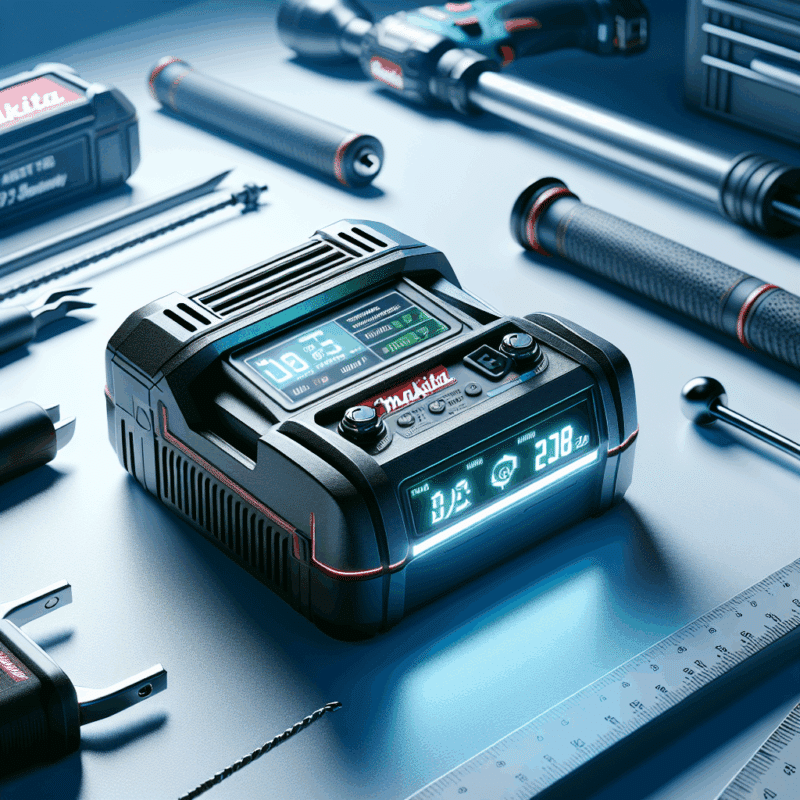

A robust fast charging job site relies on technology that prioritises both performance and safety. Chargers with higher amp ratings (e.g., 8A or 12A outputs) drastically reduce waiting times while maintaining optimal charging profiles. Unlike older models, today’s intelligent chargers monitor battery temperature and charge cycles to ensure longevity.

Intelligent safety features, such as overvoltage protection, automated shut-off, and cell balancing, prevent damage to both the battery and the tool. With the rapid pace of construction, worker safety and equipment reliability are paramount. Selecting a charger without these integrations can jeopardise hard-earned progress and introduce regulatory compliance issues.

Modern fast chargers also support multiple chemistries and voltages, accommodating a site’s entire ecosystem of tools. Look out for future-proofed equipment that supports wireless diagnostics reporting or connects with fleet management apps for battery tracking and alerts.

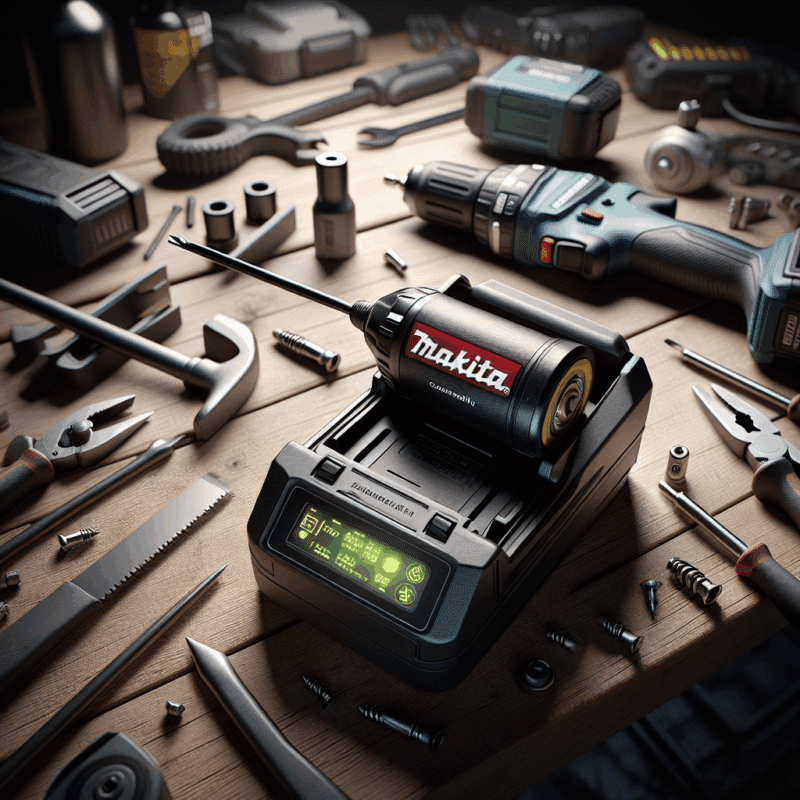

Case Study: Makita Job Site Performance Boost

What Companies Are Reporting After Switching

When a London-based contractor specialising in residential developments transitioned to a fast charging job site using Makita’s rapid dual-port chargers, the results were immediate. Task completion times saw a 23% improvement within the first month. The core benefit stemmed from reduced downtime between tool usage cycles, especially for high-drain equipment like rotary hammers and 36V saws.

The transition reduced their weekly overtime costs by nearly £1,600 across two projects. Project managers also noted higher morale among teams, as tradespeople no longer had to compete for scarce power resources or halt progress just to charge batteries. The centralised charging stations were weatherproof, mobile, and included surge protection—making them ideal for segregated zones across multiple floors.

Further enhancements included pairing certain chargers with battery health tracking apps, allowing the supervisor to cycle batteries systematically and prevent failure during critical operations.

Reducing Overtime: Measurable ROI from Charging Upgrades

Productivity Metrics from Top UK Contractors

Data from a recent industry survey revealed that fast charging job site upgrades yield a measurable return on investment (ROI) within three to four months for most mid-sized firms. This rapid recovery period comes from a combination of higher daily tool usage time, reduced labour redundancy, and fewer missed deadlines—all of which directly impact earnings.

For example, contractors working under strict conditions where work must be approved before closing phases can particularly benefit. With fast charging, the lag between tool outages and task continuation shrinks dramatically, enabling inspections and handovers to remain on schedule. Several UK-based firms recorded time savings equivalent to one full day per fortnight, a notable gain in the construction calendar.

Beyond simple manpower metrics, digital energy monitoring is helping site managers calculate the power-to-productivity ratio also known as watts-to-output analysis. This form of reporting further supports the use of advanced charging systems in job environment evaluation frameworks.

Battery Health Myths: Is Fast Charging Risky?

Balancing Speed vs. Longevity

Concerns around reduced battery lifespan due to fast charging are largely unfounded—especially when modern lithium-ion battery systems are charged using certified intelligent chargers. A fast charging job site does not equate to reckless high-voltage overclocking. Instead, it involves controlled acceleration of the charging cycle supported by microprocessors and temperature sensors.

Batteries used in commercial construction scenarios are designed to withstand high duty cycles. Provided proper storage, ambient site temperatures, and ongoing maintenance are upheld, the lifespan of a battery is minimally impacted by fast charging models. In contrast, poor charging habits—like overcharging or using generic, incompatible chargers—degrade battery integrity most significantly.

Manufacturers such as DeWalt, Bosch, and Milwaukee now offer fast chargers tailored to maintain battery health. Some of these units include adaptive programming that adjusts currents based on past battery behaviour. This ensures both safe operation and extended asset life—even in intense worksite conditions.

What to Look for in a Site Charger

Choosing the Right Features for Your Workflow

When equipping a fast charging job site, the specification of the charger cannot be overlooked. Essential features to look for include dual or quad-bay capabilities, simultaneous multi-voltage charging, rugged casing (preferably IP54 or higher), rapid cooling, and real-time battery diagnostics screens.

Charger compatibility with your existing tool framework is crucial. Cross-brand charging is still rare, so consider long-term brand alignment. Also look at advanced features such as countdown timers, auto-locking ports, and Bluetooth connectivity to apps that alert users when batteries are ready.

Finally, consider the energy source. Some of the most effective sites use hybrid charging setups where mainline electricity is supplemented with solar panels or portable generators during remote projects. Smart plug compatibility for off-peak charging can also lower your energy bills significantly.

Real-Time Charging = Continuous Tool Readiness

Uptime Translates to Lower Labour Costs

Keeping tools operational with minimal recharge windows means crews avoid breaks that aren’t planned or billable. A fast charging job site design aligns battery swaps with logical workflow pivot points, like tea breaks or clean-up periods. This ensures that teams return to work fully equipped and in sync.

Efficient charger deployment reduces the friction around tool readiness. It also limits the need for spare battery stockpiling—often a costly hedge against downtime. While high-output chargers might carry a higher upfront cost, their ability to ensure every tool is always ready pays for itself in weeks, not years.

Labour expenses driven by forced idling and waiting are among the least productive spendings in a construction budget. When every productive second counts, enabling real-time readiness is one of the smartest ways to protect your bottom line.

Voices from the Field: Contractor Perspectives

What the Teams Say About Fast Charging

On the ground, fast charging job site crews consistently report improved morale and easier project flow. “We used to waste nearly twenty minutes every time we ran out of battery mid-task,” says Billy Hawkins, site manager for a Manchester refurbishment contractor. “Now, there’s always another battery ready to go. It’s seamless.”

Workers in trades like electrical, HVAC, and finishing tend to feel the impact most acutely. They note a sharper pace and greater schedule adherence. Perhaps more importantly, senior staff appreciate the reduction in health and safety concerns. Fully powered tools reduce user fatigue and boost precision—less strain on wrists and fewer mistakes made under low battery conditions.

Accountants and operations managers are also attuned to the drop in overtime claims and energy usage. By optimising charging patterns and battery rotations, teams are learning to do more with the same—if not less—resources. For many, the shift to fast charging has been not just a benefit, but a necessity.

Our Picks for High-Impact Fast Chargers

Top-Rated Models for Construction Crews

Among the top performers in the UK market for fast charging job site applications are the Milwaukee M18 Dual Bay Rapid Charger, the DeWalt DCB104 4-Port Fast Charger, and the Makita DC18RD twin charger. Each offers rugged build quality, wide voltage compatibility, and notably fast turnaround rates of 30–60 minutes for standard Li-Ion batteries.

For sites with battery-intensive workflows, consider portable charging trailers or modular charging lockers by brands like RAM Mounts or Hilti Fleet System. These allow for off-grid charging setups, making them ideal for rural projects or multi-storey developments where power access varies by location.

Each of these tools has proven successful for fast charging job site implementation, with contractor endorsements, positive ROI anecdotes, and regulatory approvals for UK use provided. For buyers looking to centralise procurement and training, see our recommended integrations at Learn more about Maximising job site productivity with efficient charging.

Conclusion: Why Time is Money on the Job Site

Ultimately, embracing the fast charging job site model is not just a technical upgrade—it’s a competitive edge. Keeping tools charged, teams moving, and projects compliant ensures both safety and profitability. As overtime costs continue to rise, eliminating pointless wait times becomes crucial. Fast chargers give you more than just charged batteries—they deliver a charged workforce.

Incorporating smart charging into your next job site will pay both immediate and compounding dividends. Connect with distributors offering job site evaluations or explore manufacturer incentives for bundled charging tool sets at How rapid charging boosts overall job efficiency or through our extended resource guide at Automating workflows for business productivity gains. You can also learn about complimentary energy audits and battery disposal best practices at Read a related article.

Great guide on fast-charging-overtime-cost-job-sites – Community Feedback

How does fast charging reduce overtime costs on job sites?

Fast charging minimises tool downtime, enabling crews to stay productive and complete tasks within standard hours. This avoids costly overtime by ensuring batteries are quickly replenished, keeping workflow continuous even on the busiest job sites.

Does fast charging harm tool batteries over time?

Quality fast chargers are designed to balance speed and battery health. Used correctly, they provide rapid charging without significant long-term damage, especially when paired with batteries rated for fast charge cycles.

What features should you look for in a job site charger?

Look for high amp output, built-in safety mechanisms, compatibility with your battery system, and robust build quality. Features like voltage displays and multi-bay support can further optimise uptime and workforce efficiency.