Myth or Fact: Can Fast Chargers Really Replace Battery Spares?

In This Article

- Fast charger myths often stem from outdated battery technology assumptions.

- Smart chargers protect battery health through internal regulation and thermal control.

- Battery spares remain essential, especially in remote or high-demand environments.

- Makita-compatible fast chargers offer top-tier performance but require OEM validation.

- Hybrid strategies combining fast chargers and spares deliver the best throughput.

- Intelligent chargers monitor and adapt to battery conditions, prolonging pack lifespan.

- Understanding real-world use cases helps define your ideal charging strategy.

- Proper planning eliminates downtime and maximises tool efficiency on site.

Understanding the Rise of Fast Chargers

Speed vs Longevity

Fast charger myths have persisted ever since the technology became commonly accessible across sites and tool inventories. While older charging methods required hours of downtime, today’s fast chargers can power up a lithium-ion battery pack in under 30 minutes. This revolution has significantly improved productivity on job sites and enabled more continuous tool use. Yet, many tradespeople and managers still question whether the speed of these devices compromises overall battery longevity. Some fear that charging too quickly degrades cells or produces excessive heat. In truth, high-quality fast chargers are engineered with smart circuitry to monitor temperature, charge cycles, and current to minimise battery wear. While all batteries inevitably degrade over time, fast charging when done correctly does not inherently reduce lifespan.

Battery Spares in Jobsite Routines

Why Spares Still Matter

Even in an environment saturated with rapid charging systems, battery spares maintain significant utility. The idea that fast chargers eliminate the need for spare batteries is one of the most dangerous fast charger myths circulating among users today. A single charger per crew or crew member can easily become a bottleneck, especially during high-demand phases. Spares serve as buffering tools and ensure that work continues uninterrupted during charging intervals. Moreover, in colder conditions or remote locations with unstable power sources, relying solely on one battery and fast charger setup can leave tradespeople stranded. Owning multiple batteries also allows better rotation, reducing the heat stress placed on individual packs. While new toolkits often include dual-charging facilities, they are not always enough on expansive job sites.

“No matter how advanced charging becomes, having one or two charged spares can mean the difference between productivity and prolonged downtime.”

Smart Charging Habits and Battery Lifespan

Developing intelligent charging habits is essential not just for preserving individual battery packs but also for debunking several fast charger myths. It’s a common belief that users should let batteries drain completely before recharging — a throwback to the age of nickel-cadmium cells. Modern lithium-ion batteries, which dominate power tool ecosystems today, actually fare better when charged before reaching complete depletion. Irregular charging, or habitually discharging batteries beyond safe levels, could exert unnecessary stress. Most quality chargers include built-in battery management systems (BMS), but user behaviour still plays a critical role.

Another damaging myth is that leaving batteries on the charger too long “cooks” them. Advanced chargers stop supplying charge once the battery reaches full capacity. Still, it’s good practice to unplug once charging is complete, especially overnight, for optimal battery health and fire safety. Applying smart routines — like rotating spare usage, not charging in extreme cold, and avoiding overreliance on any single battery — prolongs both power and performance.

Makita-Compatible Fast Chargers Explained

Makita, one of the most trusted tool brands globally, has fast become synonymous with innovation in battery technology. Makita-compatible fast chargers are engineered to optimise not only speed but also safety, battery memory, and multi-pack efficiency. Despite these benefits, several Makita-specific fast charger myths have cropped up. For instance, some users believe third-party fast chargers compatible with Makita tools offer the same protections as OEM (original equipment manufacturer) chargers.

This is not entirely accurate. While many aftermarket products promise compatibility, they do not always integrate intelligent charge regulation or thermal control circuits that genuine Makita models feature. Always opt for OEM products or certified equivalents. Genuine Makita fast chargers utilise forced-air cooling, digital signal logic, and thermistor feedback to adjust charging dynamics in real-time, something cheaper models often replicate in voice but not in function.

Modern Charger Safety Features: Myths vs Technology

Safety is another realm where fast charger myths thrive. Older generations of users frequently reference incidents involving swelling batteries or overheated packs from sub-par charging technology. Although poorly made chargers can still be a risk, most reputable brands incorporate cutting-edge safety features. Today’s intelligent chargers include features such as:

- Over-voltage protection

- Thermal regulation systems

- Cell-balancing circuits

- Auto-cut-off processors

Another myth worth dispelling is the notion that faster charging must automatically produce excessive heat. In truth, only poorly regulated electrical flow causes harmful temperature spikes. A high-quality fast charger continuously monitors internal pack temperatures and halts operation if safe parameters are breached. As a result, using well-designed equipment from trusted sources significantly mitigates safety risks often cited against fast charging.

Real-World Scenarios: When to Use Spares

Not all tool users have the same work routines, and dismissing the role of spare batteries in favour of fast chargers alone is another of the enduring fast charger myths. Consider a fencing contractor working hundreds of metres away from any electrical mains or generator. A collection of fully charged spare batteries proves far more practical than repeatedly returning to a remote station. Similarly, demolition crews using high-drain saws or grinders may find it more efficient to carry spares rather than wait for rapid recharges, however quick those may be.

Spare batteries are also a lifeline during power outages or faults within site generator systems. Pairing spares with fast chargers ensures redundancy, applicable during peak workloads or technical disruptions. For mobile teams operating in shifts, spares can be rotated across crew members to maintain momentum. These nuanced use cases highlight that while fast charging technology adds immense value, it doesn’t serve every scenario alone.

Common Misconceptions About Rapid Charging

Among the most widespread fast charger myths is the claim that rapid charging erodes a battery’s total charge cycle count. In practice, lithium-ion batteries rated for fast charging are designed to handle quicker current infusion without chemical damage. Issues typically arise only when low-quality batteries or incompatible fast charging stations are employed.

Another fallacy is that fast charging causes permanent capacity loss. In most tests, the performance difference between fast and slow-charged batteries is minimal. Good charger design ensures cell voltages remain balanced regardless of charging rate. Also, fears about radiation or magnetic interference are completely unfounded — no modern charger emits unsafe radiation. Charging tools near electronics or sensitive devices, a concern raised in older online forums, presents no real risk in regulated settings.

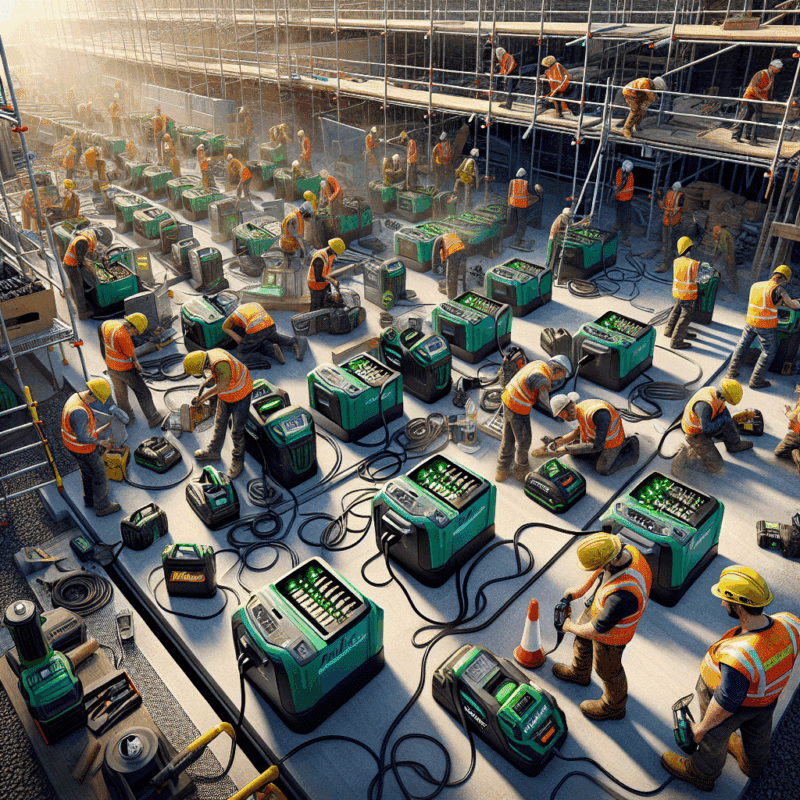

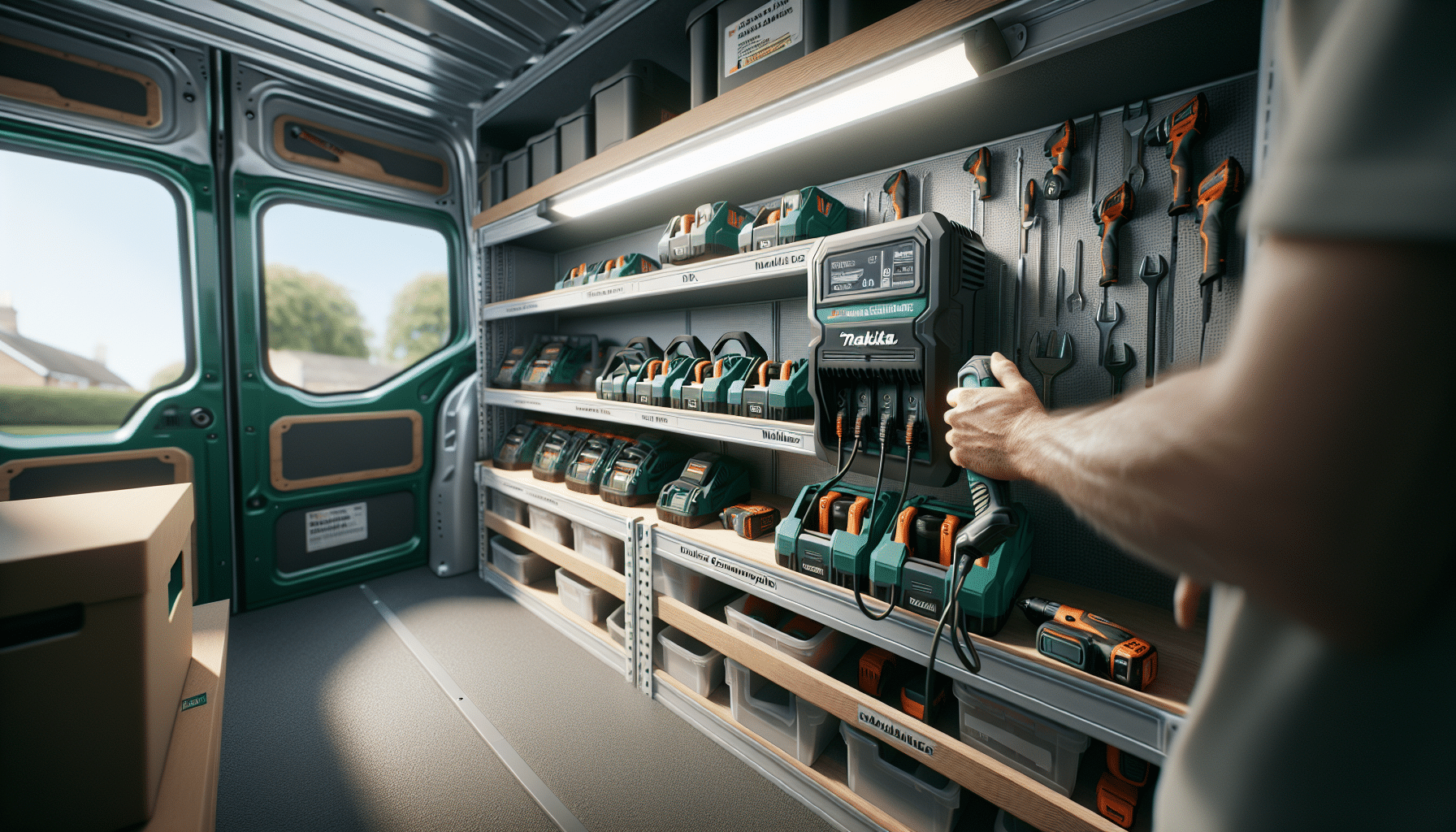

Team-Based Usage: Scaling Onsite Power Demand

Construction and maintenance teams must account for aggregate power usage across shifts. One worker operating with a fast charger may find no faults, but scale that routine across ten users and shared outlets become congested quickly. This is where one of the most persistent fast charger myths reemerges — the belief that mass adoption erases the need for good energy planning.

In reality, coordinating fast charger distribution with suitable backup batteries per worker yields the most seamless results. Teams benefit greatly from a hybrid approach: two batteries per tool operator, one charging, one in use, sometimes augmented by extra banks.

Even with a centralised fast charging station, travel between work zones and charging points presents logistical delays. Therefore, decentralised spares improve uptime. Workflows need auditing to decide ideal charger-to-user and battery-to-tool ratios.

Intelligent Chargers and Battery Health

High-end chargers now perform diagnostics and deliver charge profiles tailored to each battery’s condition. Intelligent models can detect cell performance drops, flag packs nearing end-of-life, and even store data over time. Dispelling fast charger myths should then start by understanding this sophistication.

Some users mistakingly believe intelligence features are mere gimmicks. Quite the opposite — data-informed charging optimises each cell refill cycle and reduces mismatched voltage levels, a top contributor to battery decay. Combine this with firmware upgrades and you’ll have a dynamic system built for longevity. By replacing generic rhythms with intelligent patterns, chargers effectively extend functional battery lives, neutralising the supposed trade-off between speed and durability.

Which Option is Right for You?

Choosing between fast chargers and spare batteries isn’t an either-or decision. The correct setup depends heavily on project type, worksite layout, power availability, and daily runtime. Low-intensity indoor tasks may need only one charger and two packs. Larger outdoor teams benefit more from a combination of rapid charging stations and a rotation system involving multiple spares.

Budget also plays a part. While buying three or four spare batteries per team member adds upfront cost, it often mitigates idle downtime. On the other hand, investing in fewer intelligent fast chargers could deliver substantial long-term cost savings by preventing battery replacements.

Final Thoughts on Charger Strategy

[CONCLUSION_CONTENT]

Great guide on myth-fact-fast-chargers-vs-battery-spares-interactive – Community Feedback

Do fast chargers replace the need for spare batteries?

Fast chargers reduce downtime, but in high-use, multi-tool environments, having at least one spare battery remains practical for uninterrupted work.

Is fast charging safe for my Makita-compatible batteries?

Yes, with certified chargers and proper voltage management, fast charging is generally safe and does not significantly harm battery lifespan.

Does using a fast charger wear batteries out faster?

Modern fast chargers with intelligent controls limit excess heat and overcharging, so battery wear is minimal when charging is managed correctly.