Rapid Chargers for Contractors: Essential Features & Site Success

In This Article

- Rapid chargers significantly minimise downtime for UK contractors.

- Intelligent safety features are essential—not optional—for crew and battery protection.

- Match your charger specs to your tool ecosystem for optimal performance.

- Durability and weatherproofing can make or break a charger’s value on UK job sites.

- Status indicators and compatibility with Makita, DeWalt, or Milwaukee tools streamline operations.

- Real-world feedback emphasises the need for multi-port, rugged, and brand-aligned chargers.

- A strategic charging setup improves team efficiency across every phase of the job.

Why Rapid Chargers Matter on UK Job Sites

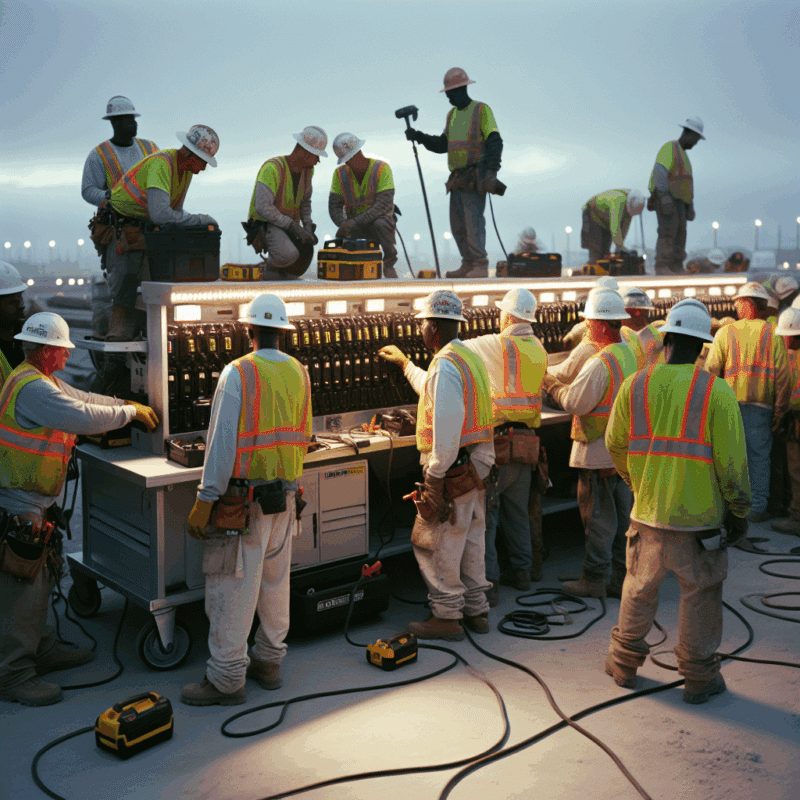

The Critical Need for Fast Turnaround

Time is money, especially in the construction and contracting world. For UK contractors, the ability to minimise downtime and keep work flowing is often the difference between profit and penalty. That’s where rapid chargers for contractors come into play. Unlike standard units, rapid chargers drastically reduce the time it takes to fully charge batteries—often delivering an 80% charge in just 30 to 60 minutes. This kind of speed isn’t a luxury. On busy sites, it’s an operational imperative.

The industry has moved heavily towards cordless tools for versatility and safety. However, batteries will eventually drain. Traditional charging equipment can stall progress, forcing workers to idle or switch from preferred tools. In contrast, a rapid charger ensures that from early morning till the last shift, teams always have the energy needed to power through tasks.

Contractors across the UK face weather uncertainties, scheduling pressures, and logistical constraints. The ability to cycle through charged batteries quickly helps maintain momentum—even when conditions test your resilience. Simply put, rapid chargers for contractors are about empowering your crew and protecting your timelines.

Top Safety Features Every Site Charger Needs

Protecting Tools and Crew with Intelligent Tech

Contractors can’t afford unnecessary accidents or tool damage on the job. Therefore, modern rapid chargers are now packed with intelligent safety mechanisms that protect both people and equipment. Look for models with built-in overcharge protection, which automatically shuts off once the battery is full. This not only extends the battery’s life but eliminates risk of overheating or combustion.

Equally crucial is temperature monitoring. UK sites often deal with ambient extremes—from winter frost to summer heatwaves. A quality charger will detect critical temperature thresholds and delay charging until conditions are safe. Integrated fan cooling systems and venting are now common features in top-tier chargers for this very reason.

Short-circuit protection and reverse polarity alerts are also essential. These stop issues before they escalate into equipment failure or electrical risk. For speed and safety, rapid chargers for contractors must combine swift charging with robust protective technologies. After all, in high-stakes environments, safety can’t be optional.

“Speed is vital, but not at the cost of safety. Choosing a charger with advanced protections pays dividends in uptime and trust.” — James Taylor, Site Manager, Leeds

Compatibility with Makita Tools: What to Look For

Makita remains a staple brand across British job sites thanks to their reliability and battery power efficiency. If you’re using Makita cordless tools, your rapid chargers for contractors need to be fully compatible to deliver the performance you expect. Look for Makita-certified units that support 18V LXT and 40V XGT battery lines, which are the dominant formats on UK building projects.

Universal chargers often struggle with delivering optimal current profiles for different battery chemistries. Instead, an OEM-compatible charger ensures maximum speed without prematurely ageing the cells. Intelligent chargers automatically calibrate voltage and current for Makita tool batteries, which is key for performance and longevity.

Another feature to examine is multi-bay support. Contractors managing teams find dual or quad-port solutions most effective. These ensure multiple Makita batteries are ready simultaneously, especially on intensive operational days.

Key Specs: Amperage, Voltage, and Port Options Explained

Understanding charger specifications allows contractors to choose the right unit with confidence. Starting with voltage: most cordless tools for professional use rely on 18V or 40V platforms. Your rapid charger should match these precisely. Undervolting or overvolting can shorten battery life or compromise power delivery.

Amperage is another critical factor. Higher amp outputs facilitate faster charges. Most rapid chargers offer outputs between 6A and 12A but prioritise units that can deliver consistent amperage under load. Variable charging profiles, which ramp up current in stages, are ideal for maintaining safe fast charging.

Port options also matter. Singe-port chargers may suffice for smaller operations, but contractors generally benefit from multi-port units. For instance, dual bays allow continuous operation—charge one battery while using another.

Lastly, USB accessory ports can be a valuable extra, especially if your team needs to charge phones, tablets or site lights alongside core tools.

Durability on Site: Choose Robust Housing That Lasts

Contracting environments are unforgiving. From dust and mud to rain and debris, your charger must cope with harsh UK site conditions. Look for IP-rated enclosures—IP54 and above are ideal—which provide resistance against both moisture and particles.

Housing made of industrial-grade ABS plastic or reinforced composite ensures resilience against drops and knocks. Rubberised corners or shock absorbers further enhance this, especially if the gear is handled frequently or transported in vehicles between jobs.

Heat-resistance is equally vital, given that rapid charging naturally generates thermal output. Well-designed shells dissipate heat quickly without warping or cracking. For contractors who work across seasons and shift types, durable construction equates to fewer replacements, leading to long-term savings.

Charging Status Indicators: No Guesswork, Just Power

Modern rapid chargers for contractors use intelligent LED indicator systems. These communicate charge progress, error codes, and readiness in real-time. Through clear, high-contrast lights or even digital screens, your team can instantly know which batteries are ready for swap.

In many models, colour-coded indicators show different stages—blinking green for ‘charging’, solid green for ‘ready’, and red for ‘error’. Some advanced units go further with integrated buzzers or mobile app notifications. These features are particularly useful on fast-moving job sites where multitasking is constant.

The fewer uncertainties your crew has, the faster the transitions and the smoother the project timeline. Accurate information lowers tool misuse and eliminates unnecessary waits.

Safe Fast Charging Without Hurting Battery Life

One of the principal concerns with rapid charging is battery degradation. Contractors rely on lithium-ion packs, which are sensitive to overcurrent, overvoltage, and high heat. Fortunately, today’s best rapid chargers balance speed with care using a “smart profile” tactic—automatically adjusting current delivery to match charge stage and battery condition.

Impressive features now include battery diagnostics. These evaluate battery health before beginning the process, thereby preventing damage to already worn-out units. Additionally, pulse charging helps reduce internal resistance build-up which, over time, diminishes capacity.

With proper charger selection, contractors can benefit from fast turnarounds without compromising tool longevity. Brands like Makita, Milwaukee and DeWalt have refined these systems to allow intensive daily use without performance drop-off.

Protecting the long-term performance of your batteries starts with selecting the right charger—one made for speed and safety hand-in-hand.

Top-Rated Models for UK Job Sites

Several models stand out among British contracting crews. The Makita DC18RD Twin Port Fast Charger is a consistent favourite. It supports the 18V LXT platform and provides simultaneous dual battery charging with active cooling and LED indicators. The unit’s compact design and robust shell make it suitable for tight, tough workspaces.

For those working with both small and large tools, the DeWalt DCB118 FlexVolt charger offers wide voltage compatibility and quick turnaround. Milwaukee’s M12-18FC charger receives excellent reviews for its compatibility and consistent delivery times across voltage ranges.

Each of these brands offers integrated safety protocols, rugged housing and smart battery diagnosis. When choosing a model, always balance specification with compatibility and brand loyalty. Sometimes, sticking within ecosystem pays significant dividends over time.

Learn more about Professional Tool Charging Solutions and Read a related article can help you compare these models further with in-depth technician breakdowns. For global reviews, visit Checklist of crucial charger station features or How SEO automation powers product discovery today.

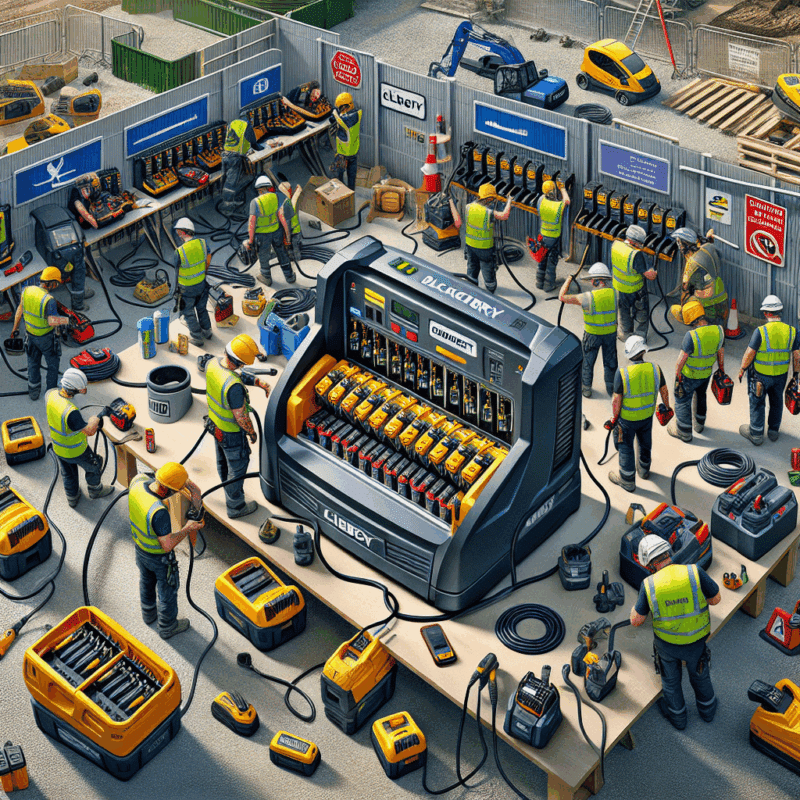

Real Contractor Insights: Charging Preferences & Pain Points

Experienced contractors share a common sentiment: downtime is more expensive than any tool. Interviews across UK regions highlight that most crews prefer dual-bay chargers and won’t compromise on LED feedback indicators. They also strongly value housing durability due to freezing mornings, wet scaffolding, and exposure to grit.

Common complaints include mismatched compatibility between chargers and third-party batteries, slow recovery times in winter, and lack of feedback during errors. Several contractors also noted the importance of silent or low-noise operation for indoor use, especially on renovation jobs in occupied spaces.

Smart money is on rugged, fast, and brand-specific units. These avoid compatibility errors and keep workflow seamless, project after project.

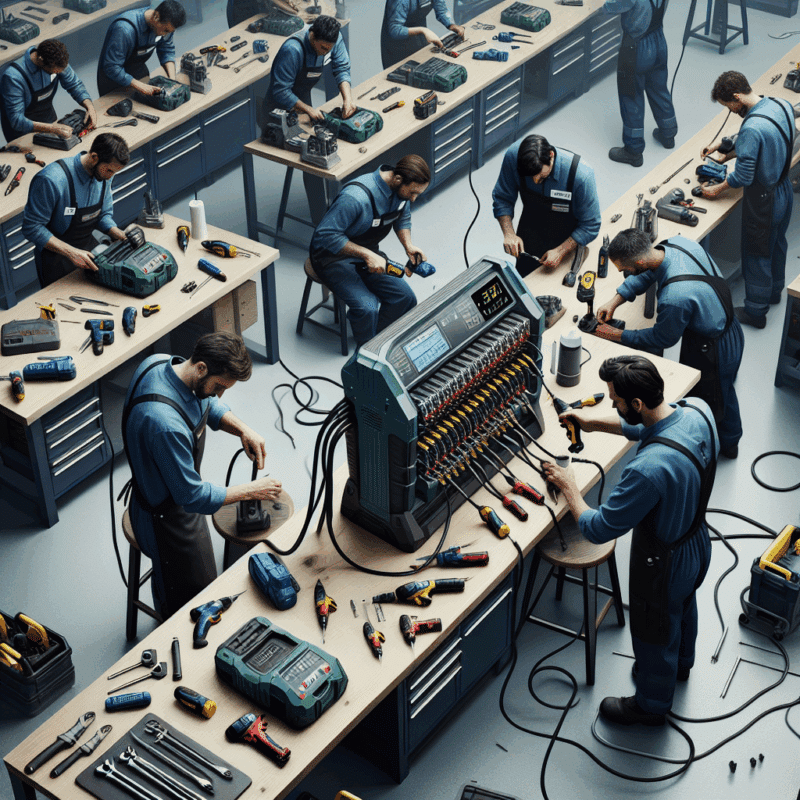

Build Your Ideal Jobsite Charging Setup

A comprehensive charging setup should include at least two dual-port rapid chargers for every four-person crew. This helps create a battery rotation strategy where nobody waits for charge. Combine chargers from the same ecosystem—Makita or DeWalt—to reduce mismatch scenarios.

Position chargers near secure, shaded areas when possible. Use weatherproof power strips and surge protectors to prevent site power issues. Labelling battery packs and using a charge log can help larger teams track usage and reduce downtime.

Adding portable battery banks for mobile or elevated work further improves efficiency. Coupled with a modular storage system, your entire fleet can stay energetic, safe and productive no matter the conditions.

Conclusion: Invest in Smarter Charging That Keeps Up

[CONCLUSION_CONTENT]

Great guide on rapid-chargers-contractors-must-have-features-explained – Community Feedback

What features make a rapid charger essential for contractors?

Contractors should prioritise rapid chargers with fast charging rates, robust build for harsh environments, compatibility with existing batteries, advanced safety features, and clear status indicators for maximum site efficiency.

How do rapid chargers differ from standard chargers on site?

Rapid chargers typically deliver higher amperage for much quicker battery turnaround, have enhanced cooling systems, and offer ruggedised casings compared to standard models designed for slower, occasional charges.

Will using a rapid charger impact my battery life?

Modern rapid chargers are engineered to balance charging speed with battery life, employing smart controls and temperature management to help prevent excess wear while maximising uptime.