Reading V/A/% Metrics: Maximise Jobsite Output with Battery Data

In This Article

- Makita battery stats (V/A/%) guide tool compatibility, safety, and runtime efficiency.

- Voltage determines power output; use appropriate volts for specific tools.

- Amperage reflects battery life—higher Ah offers longer runtime but may require longer charge cycles.

- Charge percentage is critical for safety—never use tools with undercharged batteries.

- Smart chargers and LCD readouts optimise decision-making and battery longevity.

- Daily integration of battery data boosts uptime and planning reliability.

- Consider charger features like visual displays, cooling fans, and smart analysis tools.

- Prevent misreadings through standardisation and battery monitoring training.

Understanding V/A/%: What Each Metric Means

Breakdown of Voltage (V), Amperage (A), and Charge Percentage (%)

When it comes to ensuring peak performance on the jobsite, knowing your Makita battery stats is absolutely essential. Three primary metrics govern how your batteries function: Voltage (V), Amperage (A), and State of Charge Percentage (%). Each of these plays a distinct role in determining not only the compatibility with specific tools but also safety, operational efficiency, and battery longevity.

Voltage (V) represents the electrical potential of your battery, essentially indicating how much power it can deliver at once. Makita batteries typically range between 12V to 40V, with higher voltage models such as the LXT 40V Max series being suited for high-power applications like concrete cutting or demolition. Lower voltages are ideal for light-duty tools such as drills or screwdrivers.

Amperage (A), or amp-hours (Ah), refers to the flow of current and directly correlates with how long your tool can run on a single charge. A 5.0Ah battery will run a tool considerably longer than a 2.0Ah variant. However, there is a trade-off in terms of battery weight and recharge time to consider.

The percentage charge indicator (%) tells you the current state of the battery’s charge. Simple yet crucial, this metric often determines whether you’ll finish a task or be left scrambling for a backup. Many Makita batteries now come with integrated LCD screens or LED indicators to clearly show battery charge in real-time.

Why Battery Metrics Matter for Jobsite Uptime

Prevent Downtime and Maximise Efficiency

Understanding Makita battery stats allows professionals to take proactive steps to mitigate downtime, which can be costly on time-sensitive projects. By tracking real-time voltage, amperage, and charge levels, workers can schedule recharges during natural workflow breaks, preventing interruptions during critical tasks. Downtime due to a dead battery doesn’t just waste a few minutes—it can halt entire operations or jeopardise deadlines.

Furthermore, being informed about these metrics can prolong tool life. Running a power tool below the minimum recommended voltage strains the motor, as it draws more current to compensate, increasing wear. Therefore, accurate voltage readings ensure you’re not inadvertently damaging your investment.

“Monitoring battery V/A/% data keeps tools operable and teams productive. Neglect it, and you risk a domino effect of jobsite inefficiencies.”

Voltage Insights: Ensuring Power Tool Compatibility

Knowing the precise voltage of your Makita battery is vital for matching it with the appropriate power tool. A mismatch not only reduces performance but can also damage equipment. For example, a 40V battery provides more power and durability for heavy-duty applications such as sawing and grinding. Meanwhile, an 18V battery is optimal for lighter use, balancing weight and performance.

Makita’s extensive line-up requires careful attention to these voltages. The LXT platform unifies 18V tools under one ecosystem, while the XGT platform offers a higher 40V Max solution for increased power demands. Switching between them without understanding their power requirements can lead to suboptimal results or even void warranties. Always ensure the battery voltage aligns precisely with your device’s specifications.

Amperage and Charging Speed: Faster Tools, Smarter Work

Amperage directly impacts runtime, but it also influences how efficiently a tool can access power. Higher amperage batteries (e.g., 5.0Ah and 6.0Ah) deliver sustained output over time, enabling high-drain tools like angle grinders or reciprocating saws to perform without slowing down. However, higher amp-hour batteries take more time to charge, which is where fast-charging technology proves invaluable.

Makita smart chargers, especially models like the DC18RC and DC40RA, optimise charging curves through active cooling and intelligent battery communication. Understanding your battery’s Ah rating enables smarter rotation and charge scheduling. This minimises tool downtime and boosts overall jobsite productivity. Never underestimate the ability of amperage awareness to streamline workflows and maximise tool performance.

State of Charge (%): The Most Overlooked Safety Metric

Among the Makita battery stats, the charge percentage is often underappreciated—yet it’s crucial for both safety and continuity. A tool that cuts out unexpectedly due to a flat battery can cause accidents, especially when dealing with intricate cuts or high-speed operations. Workers should always check the state of charge before beginning any task to prevent stop-start inefficiencies and dangerous scenarios.

Charge indicators have evolved significantly. Modern Makita batteries provide five-bar LED displays and accurate digital readouts. Some even offer Bluetooth-enabled feedback via smart apps. With technology on your side, there’s no excuse for running a battery dry in critical moments. Keeping batteries sufficiently charged and monitoring states proactively leads to safer, smoother workflows.

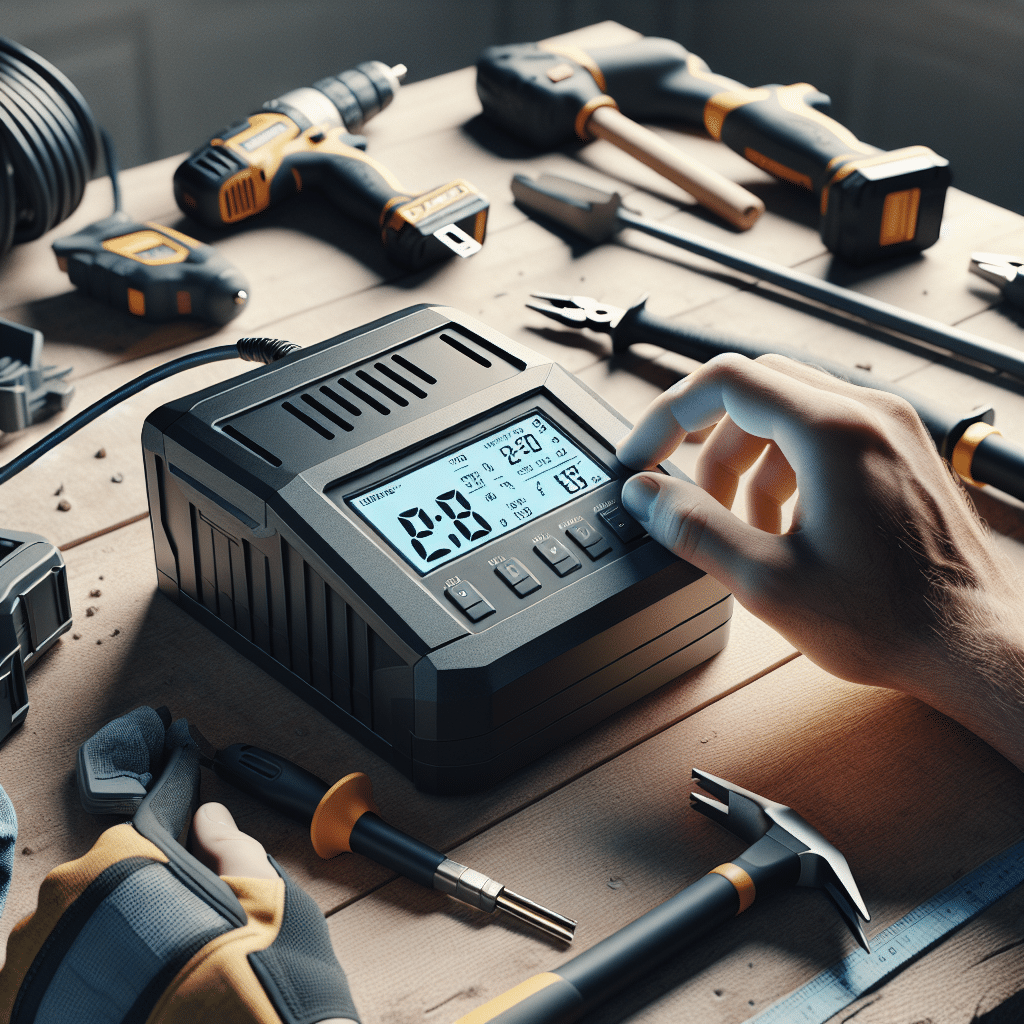

How LCD Readouts Improve On-Site Decisions

Makita has integrated increasingly sophisticated displays into many battery systems, including backlit LCDs on premium battery units. These readouts often present a combination of all three key metrics—voltage, amperage, and charge state—helping users make informed decisions in real time. Rather than relying on guesswork, workers can now verify battery integrity before attaching it to a high-demand tool.

This feature becomes particularly useful on larger projects where tools and batteries rotate between multiple team members. Consistency in charge monitoring avoids conflicts over battery availability and ensures that even in shared environments, decisions are led by data, not assumption. It’s a small upgrade that leads to major gains in team synchronisation and efficiency.

Integrating Battery Data into Daily Routines

Integrating Makita battery stats into your daily routines doesn’t require new tools but a new mindset. Before beginning work, a quick group rundown of available batteries and their charge levels can prevent misallocations. Creating a battery board or digital tracker within the tool crib allows foremen to quickly ascertain who has what and plan accordingly.

On larger contracting jobs, adding battery metrics to end-of-day checklists ensures batteries get recharged overnight or rotated sensibly. Additionally, establishing recharging zones adjacent to primary workspaces cuts down on commuting time between tasks and charging bays. Daily integration of V/A/% monitoring builds a culture of foresight—fuelled by real numbers, not vague estimations.

The Role of Smart Chargers in Modern Sites

Smart chargers have revolutionised how professionals approach battery management. Makita’s range includes chargers that not only communicate with batteries but also analyse charging data and optimise recharge sequences. This maximises battery lifespan and drastically reduces charge times through active cooling fans and adaptive voltage regulation.

Smart charging stations can even monitor ambient temperature to ensure the battery is charged under ideal conditions. Overheating is a major factor in battery degradation, so having a charger that naturally adapts to the working environment proves invaluable. Consider investing in network-connected smart chargers that store historical data—valuable for long-term equipment planning and replacement cycles. Learn more about Power tool battery data and jobsite performance

Common Misreadings and How to Avoid Them

Misinterpreting Makita battery stats is more common than you might expect, particularly on high-intensity jobsites where distractions are frequent. For instance, assuming a full LED bar equates to full voltage capacity is incorrect—batteries can appear fully charged while delivering reduced output due to age or extreme cold. Moreover, misreading amperage indicators could lead to misuse of batteries with incompatible tools, shortening product life.

To avoid such errors, invest time in proper training and standardise the use of advanced indicators or apps available for Makita smart units. Avoid generic, third-party chargers that don’t interpret battery health accurately. Always consult the product manual or refer to resources such as Read a related article and Optimising workflows with real-time performance metrics for up-to-date reading protocols.

Pro Tips for Monitoring V/A/% Effectively

Effectively monitoring your V/A/% stats involves a mix of habit, technology, and awareness. Employ a rotation strategy—label each battery numerically and cycle usage to ensure even wear. Use Makita’s battery monitoring apps or compatible third-party voltage readers for deeper diagnostics. Checking battery health weekly can catch early signs of imbalance or degradation.

Consider initiating a battery maintenance schedule that includes contact terminal cleaning and full discharge-to-recharge cycles for calibration. Share watchlists across teams noting underperforming units to streamline replacements before critical failure. For extended jobs, keep a charging shift roster. This way, batteries never bottleneck progress. Explore additional insights from How data boosts productivity in fast-paced sectors to complement your monitoring strategy.

Choosing Chargers Based on Data Readability

It is not just about charging—it’s about how clearly your charger communicates your battery’s health. Select Makita chargers that come with visual LCDs, audible alerts, and heat detection. The Makita DC40RA, for instance, provides rapid feedback and can show faults immediately upon docking. Tools are only as healthy as the power sources they rely on, so the ability to quickly interpret V/A/% data on the spot is paramount.

Match your charger with the kinds of batteries you use most often. High-capacity batteries benefit from intelligent load-balancing features more than low-Ah variants. Invest in units with smart interfaces if battery performance analysis is a daily requirement. Data visibility is the first step in forging a more efficient and prepared team.

Conclusion: Turn Metrics into Measured Results

In the high-stakes world of construction and contracting, metrics aren’t just numbers—they’re the foundation of your performance. By understanding Makita battery stats such as voltage, amperage, and percentage charge, professionals can work smarter, safer, and more efficiently. These metrics guide user behaviour, inform purchasing decisions, and prevent unnecessary downtime.

Whether you’re maintaining a small fleet of tools or managing a massive crew, incorporating V/A/% data into your routine transforms chaotic workflows into streamlined systems. Expertise begins where data meets action. It’s time to stop guessing and start measuring.

Great guide on essential-metrics-v-a-percent-jobsite-output – Community Feedback

What do V, A, and % mean on Makita battery chargers?

V stands for volts (battery voltage), A for amps (charging current), and % indicates the charge level. Monitoring these helps optimise charging and tool performance.

How can V/A/% readings improve jobsite efficiency?

Tracking voltage, amps, and charge percentage helps prevent downtime by optimising charge cycles, proactively replacing batteries, and ensuring tools are always ready.

Which battery metric is most important for power tool safety?

Charge percentage (%) is crucial, but voltage (V) and amperage (A) readings also matter for safe, optimal tool operation, especially with high-capacity batteries.