Set Up the Ultimate Makita Battery Bench for Team Efficiency

In This Article

- A dedicated Makita battery bench boosts team productivity and ensures battery availability.

- Integrate high-quality rapid chargers and arrange them based on usage frequency.

- Ensure proper ventilation and use cooling systems to prolong battery life.

- Label all batteries to maintain transparent ownership and improve accountability.

- Implement FIFO systems to evenly rotate battery usage throughout the fleet.

- Avoid charging overloads through proper circuit design and isolation.

- Learn from real-world configurations to avoid common design flaws and oversights.

- Integrate the battery bench within workflows to maximise efficiency and safety.

Why a Dedicated Makita Battery Bench Matters

Power Management Across the Team

When teams operate with a wide array of cordless Makita tools, a unified Makita battery bench becomes a non-negotiable part of the workflow. Such a setup not only reduces downtime by keeping batteries charged but also minimises confusion over power tool ownership and battery allocation. This bench functions as the central hub for all battery-related activities, from charging and cooling to storage and rotation management. Without a proper system in place, teams may experience conflicts over battery usage, missed charging opportunities, and even costly equipment damage due to overcharging or environmental stress. Adequate power management elevates workflow efficiency and keeps the team aligned.

Essential Components of an Efficient Charging Station

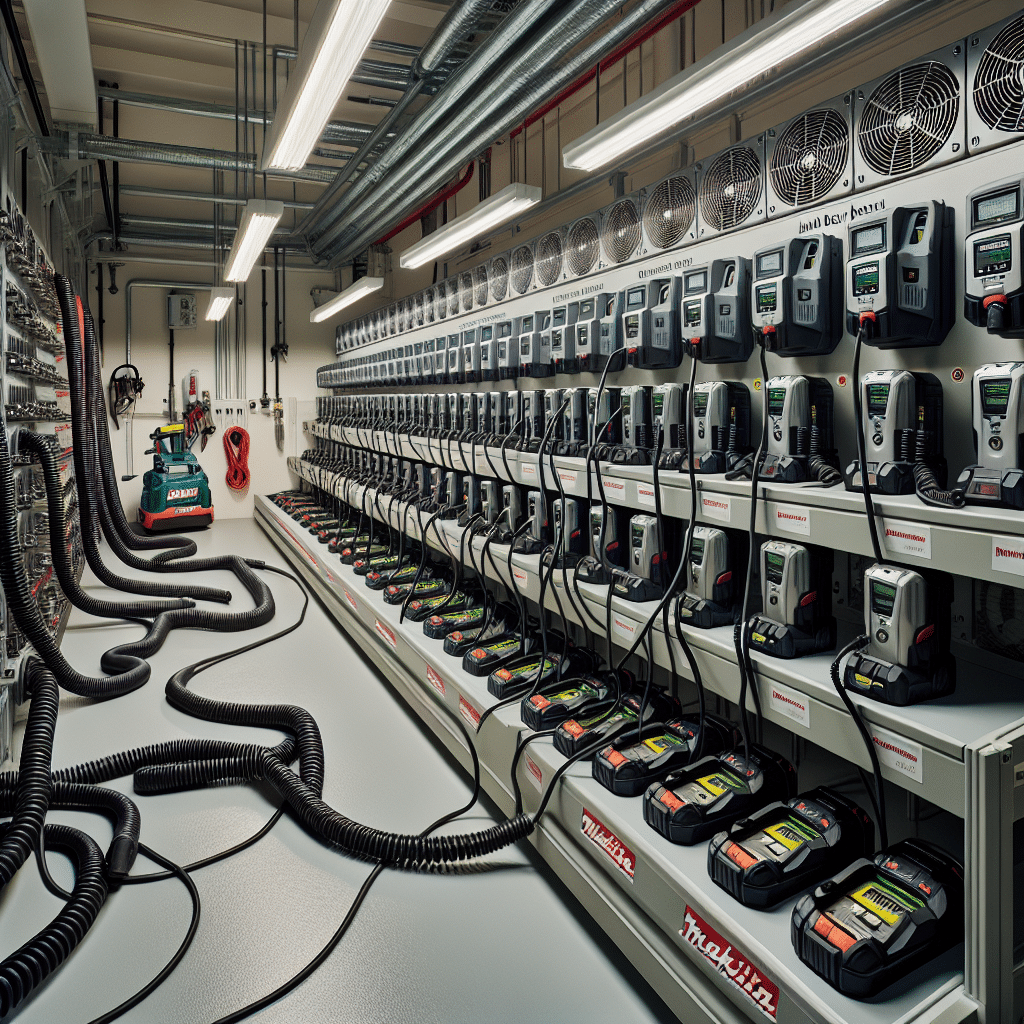

Bench Structure, Cabling, and Ventilation

The structural design of a Makita battery bench significantly impacts its effectiveness. A sturdy, heat-resistant workbench or wall-mounted station is highly recommended. Use high-grade plywood for custom builds or retrofit existing shelves with metal enclosures to create segregated bays. Each bay should accommodate a charger, sufficient cabling, and space for cooling airflow. Cabling should be neatly cable-tied or routed through conduits, which prevents trip hazards and improves aesthetics. Ventilation must not be overlooked. Batteries emit heat during charge cycles, and if airflow is inadequate, the lifespan of those batteries can be severely reduced. Installing vents or small extraction fans behind the bench ensures that heat escapes effectively. Safety signage and clear labelling are also paramount to educate users and reduce misuse. Learn more about Cordless Power Tool Charging Solutions

“A well-designed Makita battery bench does more than charge batteries—it supercharges productivity.”

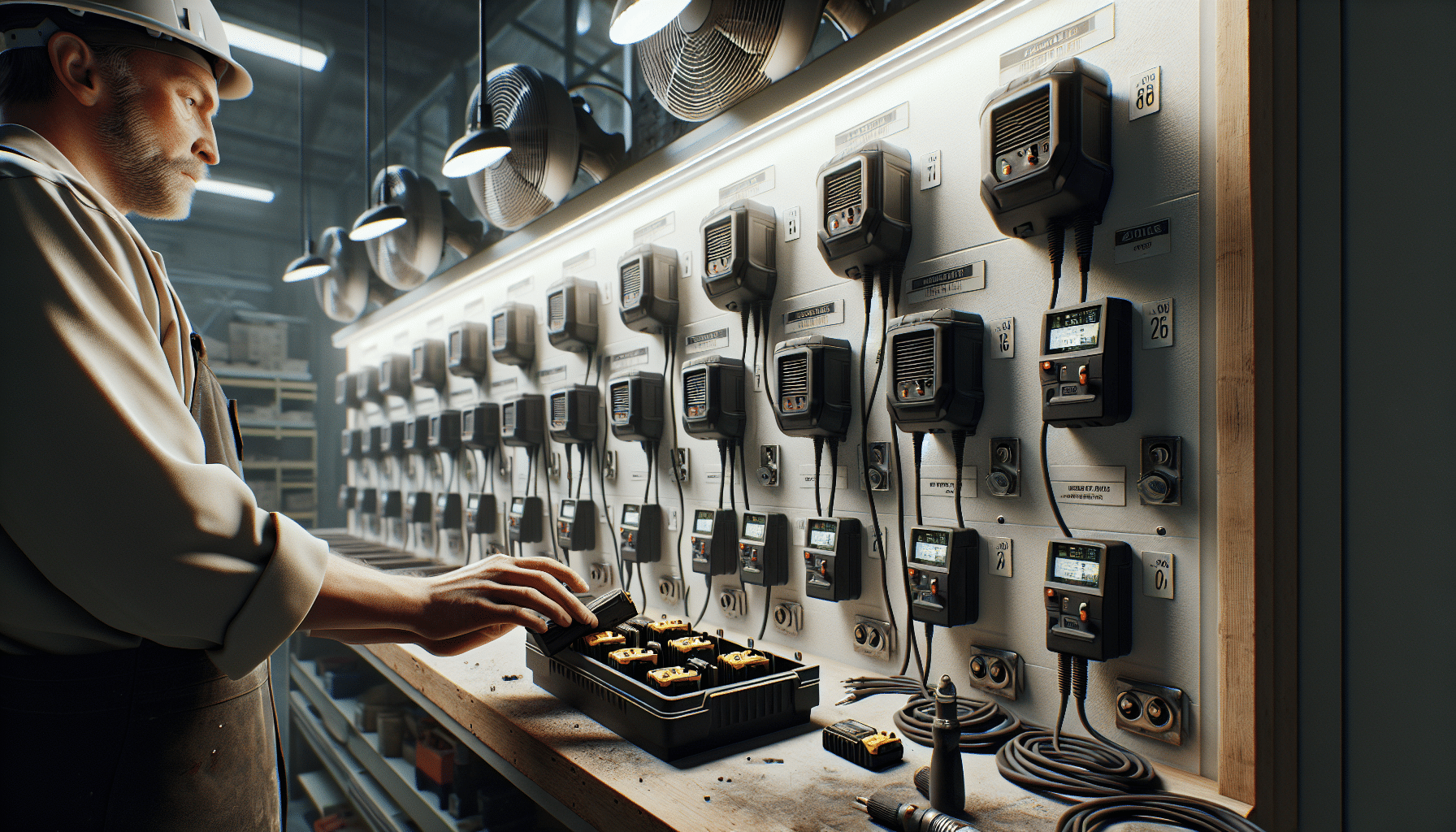

Choosing the Right Rapid Chargers

Selecting the correct Makita chargers is crucial when building a scalable Makita battery bench. Makita offers rapid dual-port and single-port chargers, such as the DC18RD and DC18RC, which can fully charge 18V LXT batteries in under an hour. For team environments, it is advisable to invest in multiple dual-port chargers to reduce bottlenecks. Ensure that all chargers are of the same model for consistency and compatibility. Integrating smart chargers with USB ports can help run diagnostic tools or charge additional devices. A top-tier charger may initially seem like a luxury; however, time savings and battery health preservation reveal clear return on investment. Chargers should be positioned based on usage patterns—heavy-duty users need closer access, whereas light users can be allocated to peripheral stations.

Cooling and Safety Measures for Battery Longevity

Most battery failures stem from inadequate heat management. To combat this issue, the Makita battery bench should include passive and active cooling techniques. Passive cooling entails separation between chargers, open slats in the bench surface, and heat-dispersing materials like aluminium plates under chargers. Active cooling options include quiet case fans and temperature-triggered ventilation systems. Overcharging is another serious concern—avoid daisy-chaining multiple chargers on a single low-capacity power strip. Instead, install fused industrial sockets with surge protection. Each charger should have a dedicated outlet to prevent overloads. Additionally, mount a central power cutoff switch to instantly deactivate all chargers in emergencies. Fire-safe enclosures add an additional layer of security, especially in dusty or volatile environments.

Labelling and Battery Ownership Systems

When multiple colleagues share a Makita battery bench, ownership confusion can stall operations. The solution is a colour-coded and labelled marking system. Use high-visibility industrial stickers to tag batteries with team member initials, department IDs, or project codes. Labelling should also extend to charging ports, chargers, and storage cubbies. Digital labelling systems—such as barcode or QR code tags that link to usage logs—provide an advanced method of tracking performance and preventing theft. Introducing a check-in/check-out ledger (digital or physical) allows operational managers to monitor turnover and gauge replacement needs. Transparency in battery allocation drastically improves trust, prevents loss, and ensures accountability across the board.

Smart Battery Rotation Scheduling

Battery wear does not occur evenly across a fleet. Some units get used intensively, while others sit idle and degrade over time. Deploying a smart rotation system can equalise battery usage. A first-in, first-out (FIFO) method is ideal. Arrange charged batteries on the top shelf, with depleted ones dropped into labelled “To Charge” bins. When batteries are replenished, the oldest go back into circulation first. For added consistency, implement a whiteboard or software tool to visually monitor daily rotations. Assign specific staff to be responsible for the battery bench each day, which spreads the routine and prevents oversight. The rotational mindset helps maximise battery lifespan and prevents newer batteries from being overused prematurely.

Preventing Charger Overload on the Bench

While adding more chargers seems like a logical way to meet demand, running too many devices simultaneously from a single circuit invites disaster. Circuit overloads can lead to fuses blowing, tripping breakers, or worse, causing electrical fires. Professional installation of a dedicated 20-amp (or higher) circuit is vital for Makita battery bench reliability. Consider installing a commercial-grade surge suppressor system and voltage meter that displays the current draw in real time. Power-efficient scheduling (half the chargers in use during peak hours, the rest overnight) can reduce stress on circuits and stagger demand. Avoid “charger stacking”, where chargers are placed on top of one another—this inhibits airflow and worsens thermal performance. How to open and repair Makita 18V batteries safely

Real-World Examples from High-Volume Sites

On a Midlands commercial roofing site, managers implemented a Makita battery bench equipped with 12 rapid chargers, labelling, and digital usage logs. Downtime dropped by 38% in the first month. Similarly, a joinery workshop in Glasgow adopted a zonal charging system and heat extractors near the bench. The result: battery failures reduced by nearly 60% over six months. Case studies validate that investing in a holistic charging system is not redundant—it’s fundamental. These teams didn’t just add outlets—they re-engineered process dependency on power tools. Workers knew exactly where to go, what battery to grab, and how to report faults. These lessons can be universally applied and adapted to all project scales. Read a related article

Integrating the Setup into Workshop Layouts

The placement of your Makita battery bench can either streamline or strangle productivity. In small shops, the station can be positioned near tool racks with adjacent cubbies for spare batteries. In larger facilities, consider multiple satellite benches strategically located around work zones. Ensure benches are never in proximity to moisture, flammable chemicals, or uninsulated openings. Lighting is also critical—under-cabinet LED strips help technicians spot chargers that are improperly seated. A dedicated charging zone establishes a natural routine and reinforces tool discipline within the crew. Incorporate ergonomic mounting heights and clear access lanes to prevent bottlenecks during tool exchanges or shift turnovers. Such integrations make the bench a productivity asset, not a workplace obstacle. Automating workshop processes to boost productivity

Conclusion: Scaling Power Without Downtime

The Makita battery bench is the unsung hero of any cordless-tool-dependent operation. From rapid charging infrastructure and cooling safeguards to smart rotation and ownership systems, each element contributes to a seamlessly powered workspace. A meticulously designed bench prevents workflow breakdowns, safety hazards, and budget-draining battery replacements. By embracing industry-proven best practices, your team can deploy a battery system that evolves alongside your operational demands. Whether you’re running a compact joinery set-up or leading large construction crews, investing in a strategic Makita battery bench is a powerful step toward operational excellence that refuses to compromise. Maintain it, scale it—and let it power your future worksite.

Great guide on makita-battery-bench-team-setup-guide – Community Feedback

What’s the ideal charger configuration for team Makita battery benches?

A smart team charging setup includes multiple rapid chargers, proper ventilation, clear battery allocation, and space for battery rotation to keep every team member productive with minimal downtime.

How can benches avoid overheating of Makita batteries during team use?

Ensure benches have cooling fans or airflow, use chargers with integrated cooling, and space out chargers to prevent excess heat build-up during simultaneous charging sessions.

Which charger maximises productivity for team sites using Makita LXT?

High-output chargers like the Torxup VoltGuard 6500, with rapid 6.5A output and multi-protection features, minimise team wait times and keep your Makita batteries ready all day.